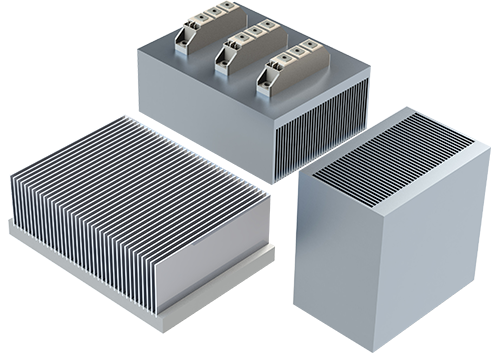

40 years experience at your service

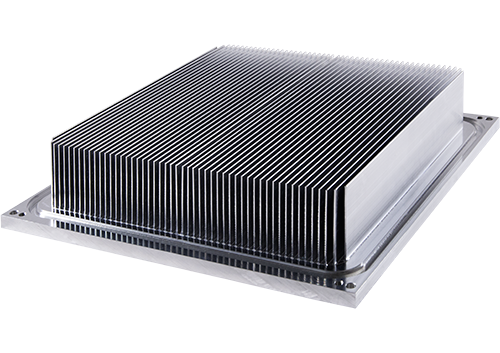

Tecnoal is active since 1985 in heat-sinks manufacturing and mechanical support for electronics.

Tecnoal is certified ISO 9001 since 2002 and the main production area covers 7000m2.

Engineers, high-tech machines and high-qualified employments support your request starting from design to end products.

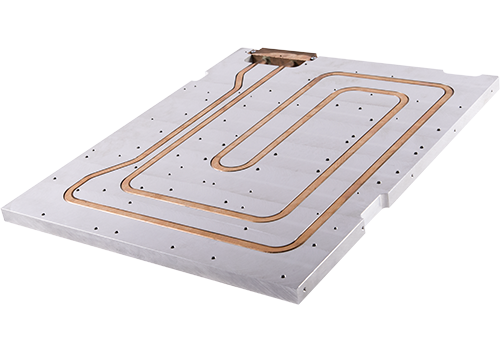

Extrusion tolerance

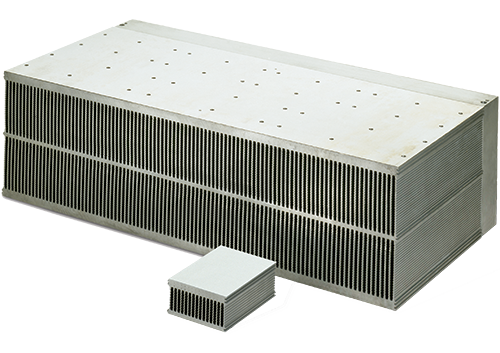

All our profiles are extruded in 6060 or 6063 aluminum alloy, in compliance with the UNI EN 755/9 standards.

For specific requirements and custom heat sinks made on drawings, tolerances of up to about 50% of these standards can be achieved.

If there are critical dimensions, which must be respected, these must be agreed in advance with the technical office.

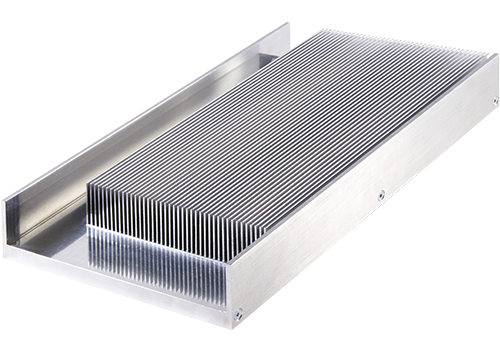

Materials and Designations

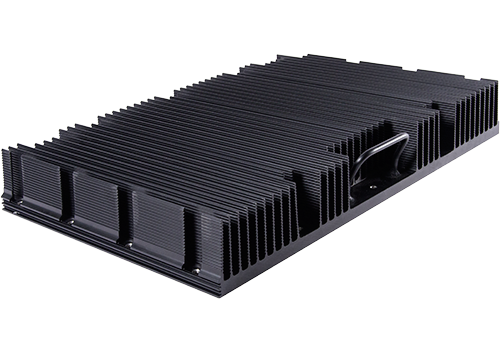

All profiles in our catalog, unless otherwise specification, are extruded in aluminum alloy EN AW 6060

Numerical designation 6060 Al Mg Si 0.5

On request is available aluminum alloy EN AW 6063.

Stato fisico T5, both 6060 and 6063

Specific weight 2.7 Kg/dm3

See materials characteristics alloy EW AW6063

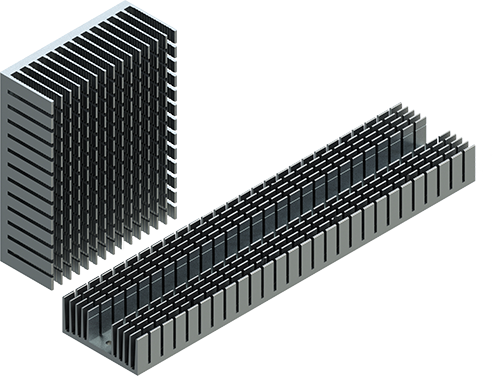

Manufacturing Tolerance

Tecnoal adopt where not specified the following tolerances:

Cut +0 -0.5

References ±0.3

Wheelbases ±0.2 (not cumulative)

Depth of thread: 2 times the diameter plus 1mm

Flattening of the component area ±0.03mm/100mm

Average roughness in the component area

(smoothing) Ra 1.6

Other workings where not specified:

average degree of precision according to UNI 22768-1-m

Acceptance criteria according to UNI EN 22768-1

Unless otherwise specified, parts that do not conform to the general tolerances prescribed must not be automatically rejected when the functionality of the parts is not compromised.

News

Tecnoal sarà presente al PCIM 2019 di Norimberga.

Ci potete trovare al padiglione 9, stand 139

Company Certified UNI EN ISO 9001

DNV Business Assurance Management System Certificate

Tecnoal S.r.l.